If I may offer my perspective as an independent watchmaker...if anyone prefers using the service center, that's up to you. Not trying to change your mind or drum up business...I already have to turn away more watches than I accept. But I want to dispel the implication that independent watchmakers will let things go that a service center won't.

Yes, Omega will typically replace more parts than an independent watchmaker will, but it's not because they are letting things go that Omega would replace. Watchmakers in service centers are essentially parts replacers, and a lot of their hard earned watchmaking skills are terribly underutilized due to corporate policies, and time constraints. They have productivity standards that must be met.

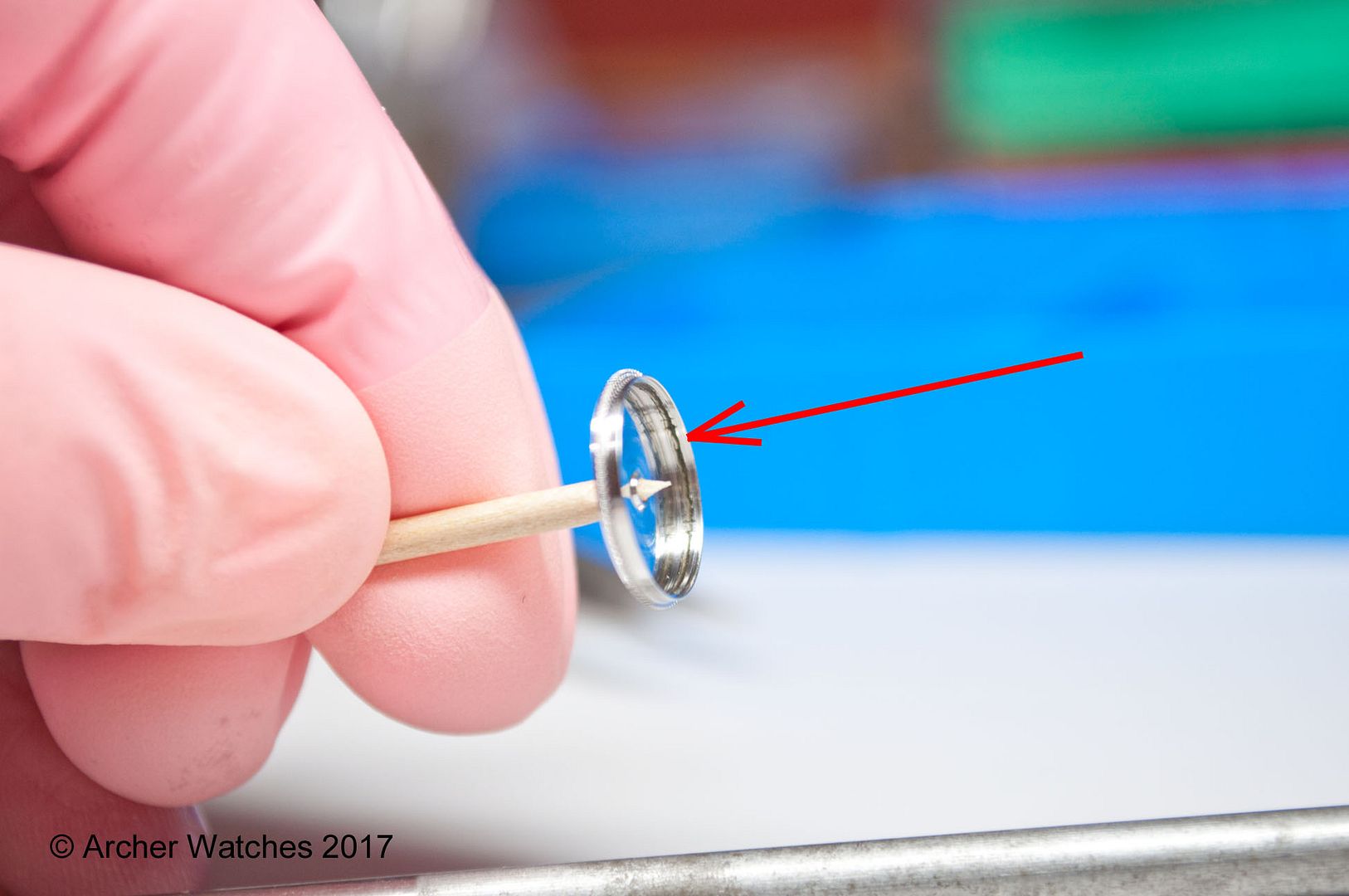

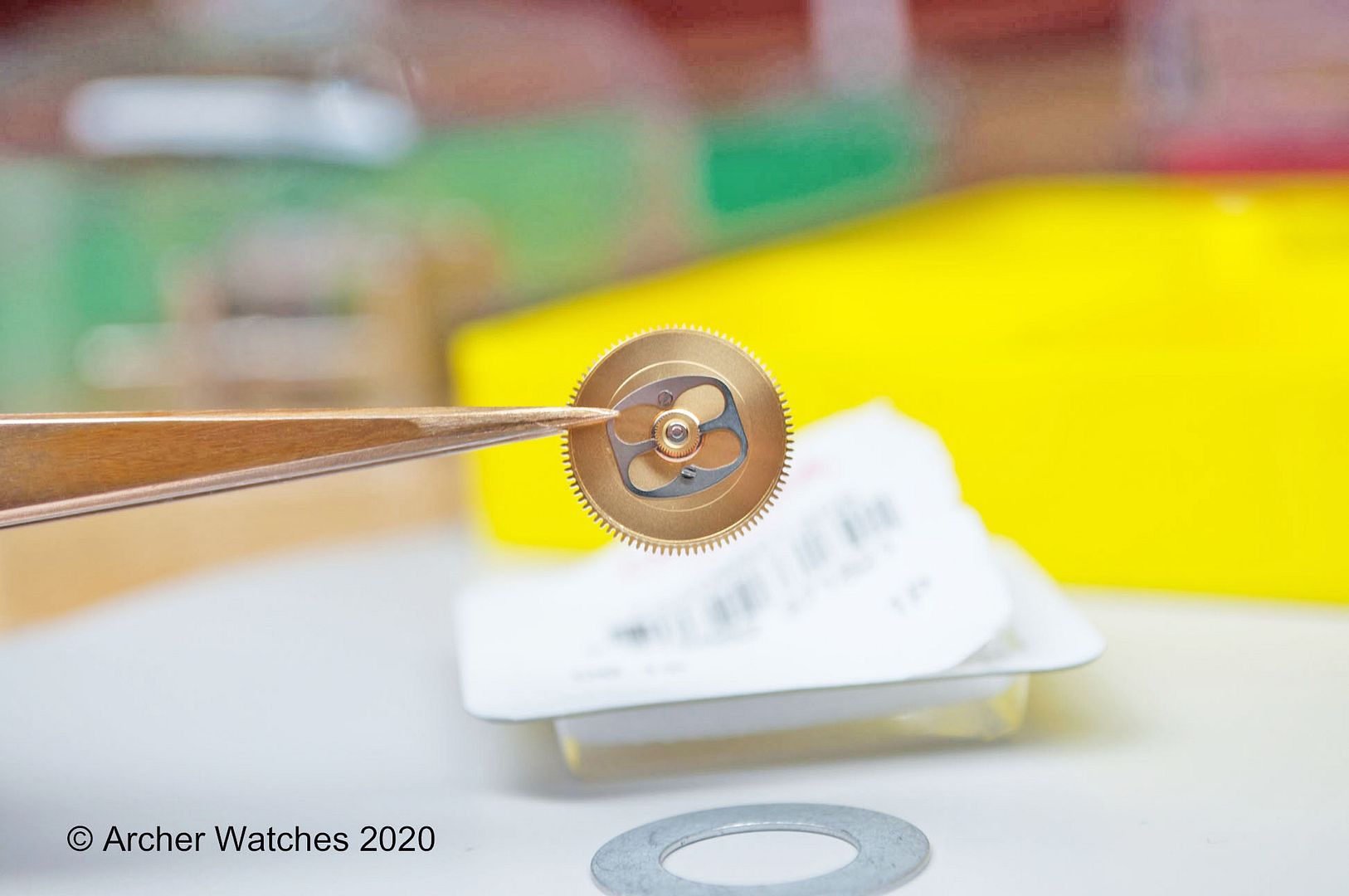

The most common example is the mainspring barrel. In a movement like the Cal. 1120 in the OP's watch, it is made of 4 parts - the barrel drum, barrel cover, barrel arbor, and mainspring. The parts that is a must to replace is the mainspring, and often the other three parts are fine. An independent will disassemble the barrel, clean it, inspect it and if it's good, applying braking grease:

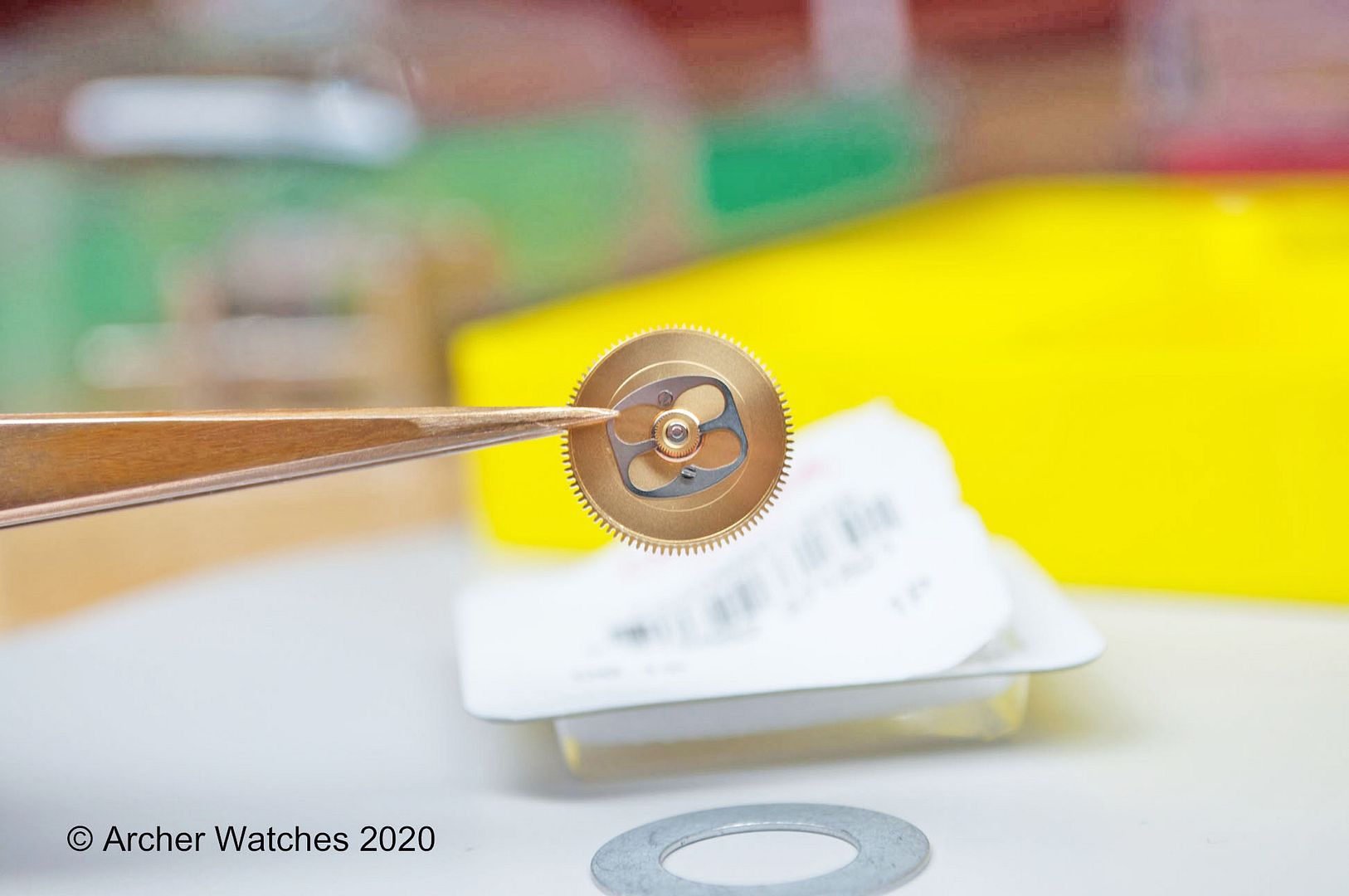

Insert a new mainspring:

And assemble the barrel:

In the service center they just grab a "barrel complete" from the stock and drop it in. They do this because it saves them a few minutes, and the result is that often the good parts are simply wasted.

They do the same with Speedmaster (321, 861, 1861) barrels, but those are made up for the same 4 parts I listed above, plus a driving pinion for the hour recorder, a friction spring and two screws to mount it all to the barrel - the whole thing gets replaced when in reality 90% of the time only the spring needs replacing.

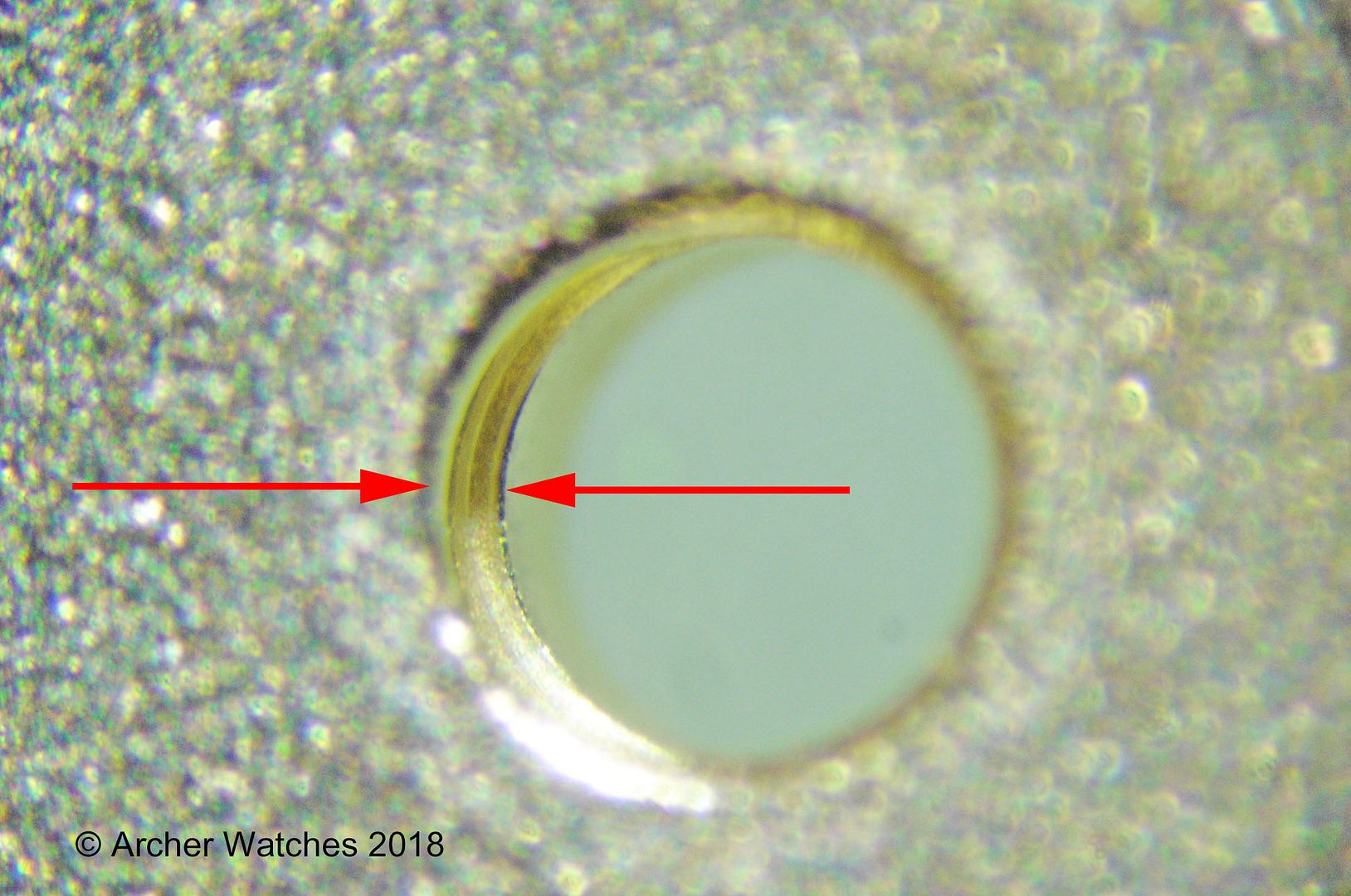

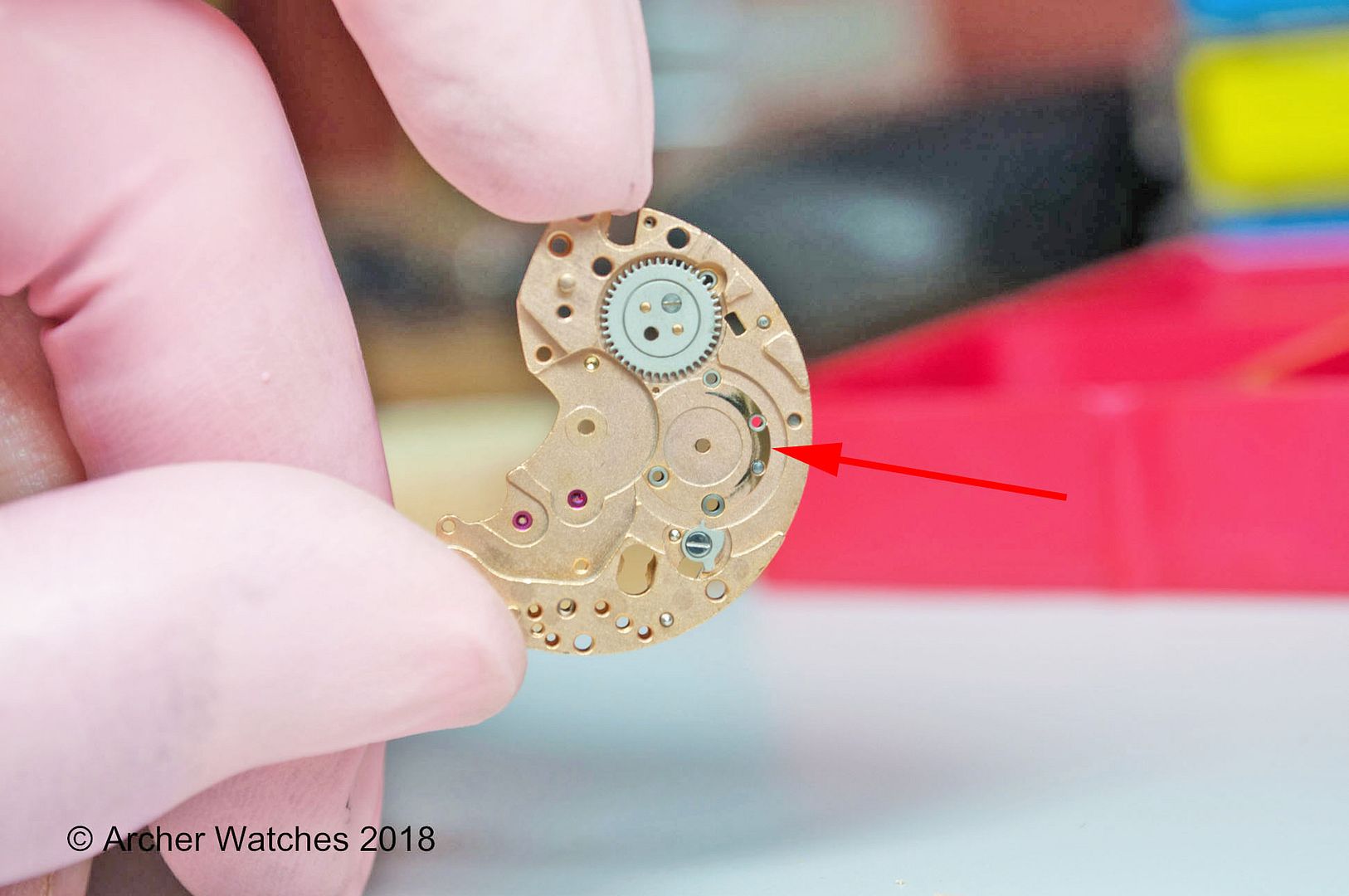

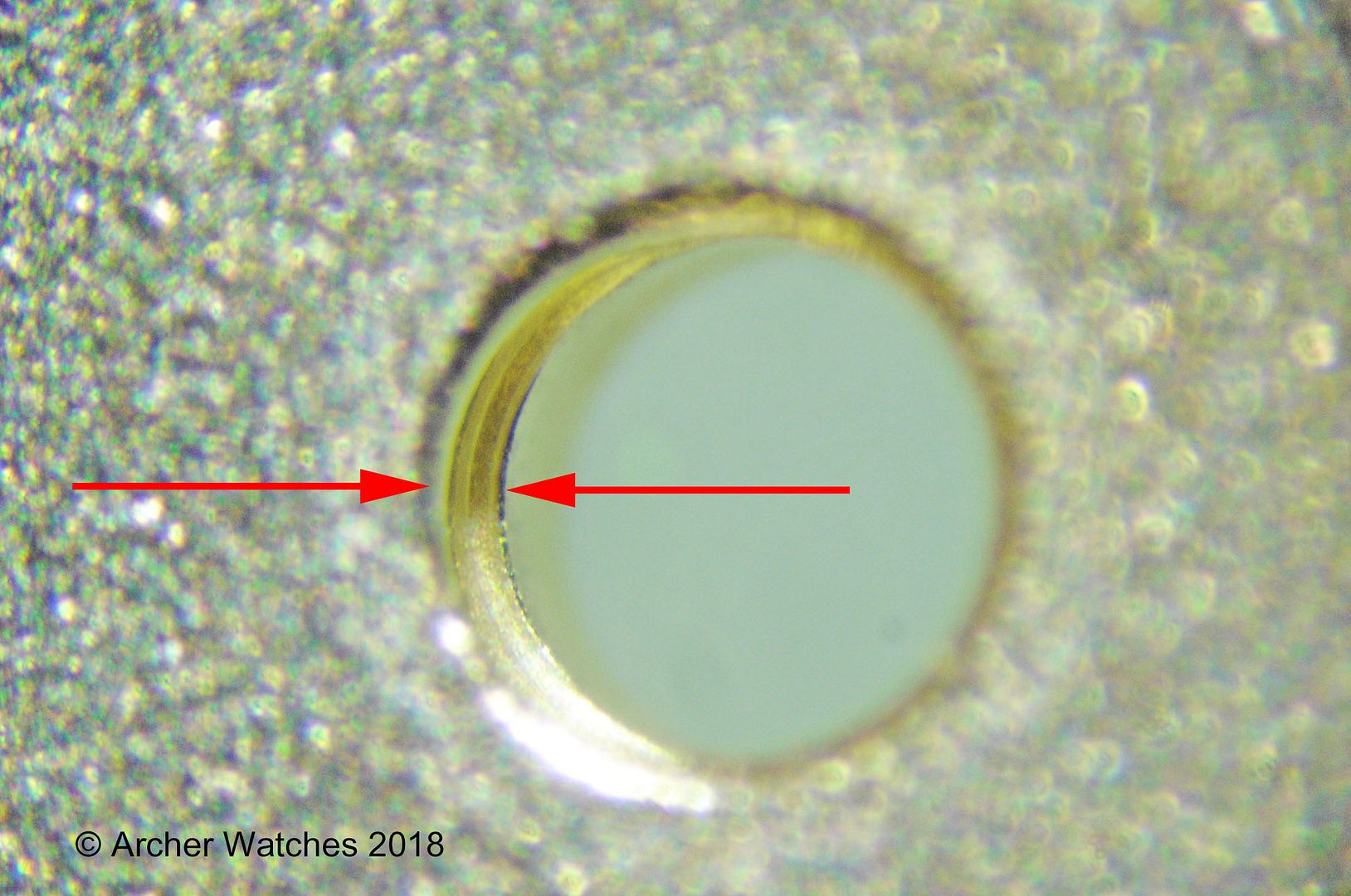

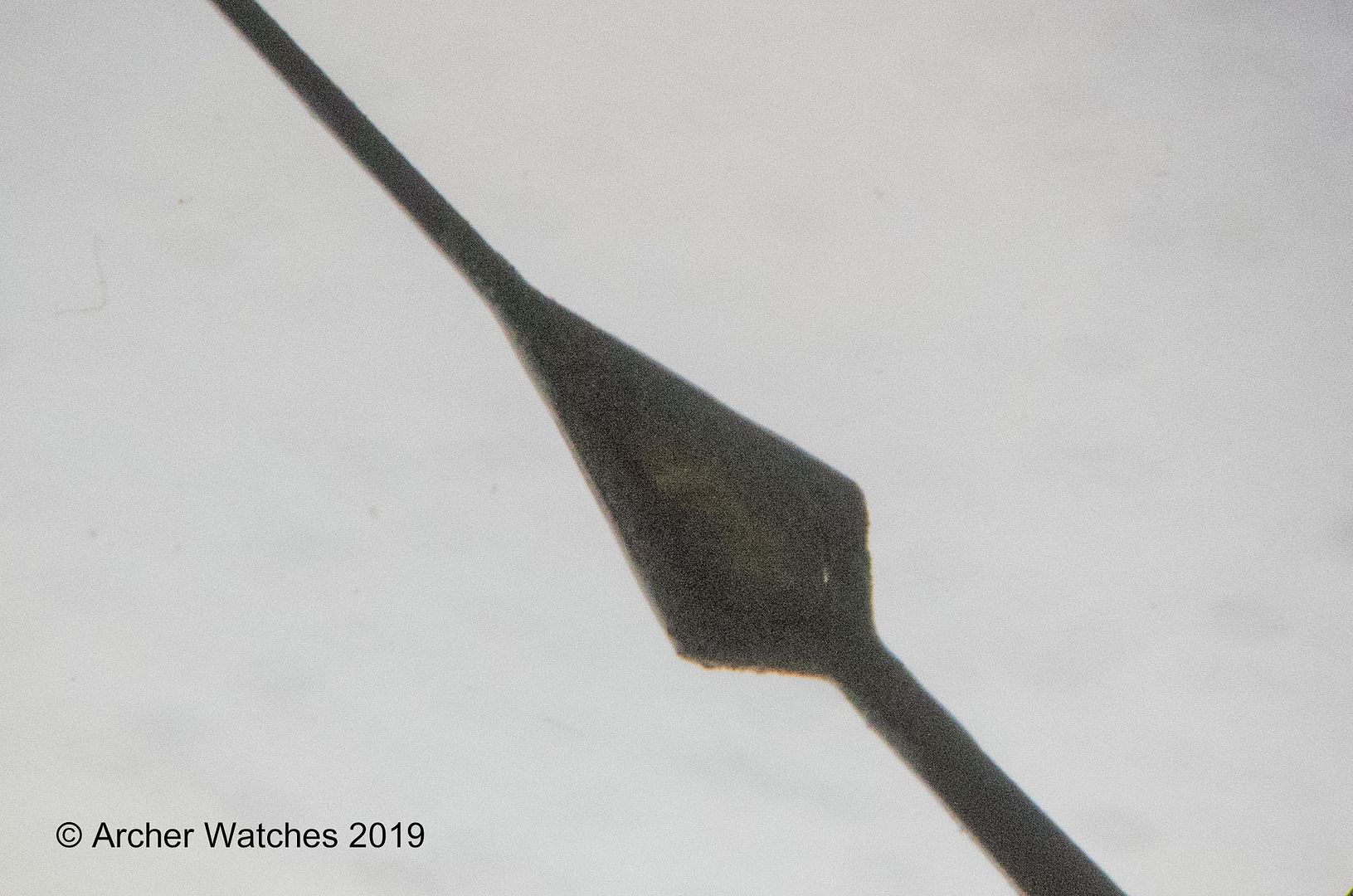

Sticking with Speedmasters, a common wear point is a hole in the primary train wheel bridge where the barrel arbor goes through the plate. The hard steel arbor rides in the soft brass plate, and over time it wears the hole in the plate oval, like this:

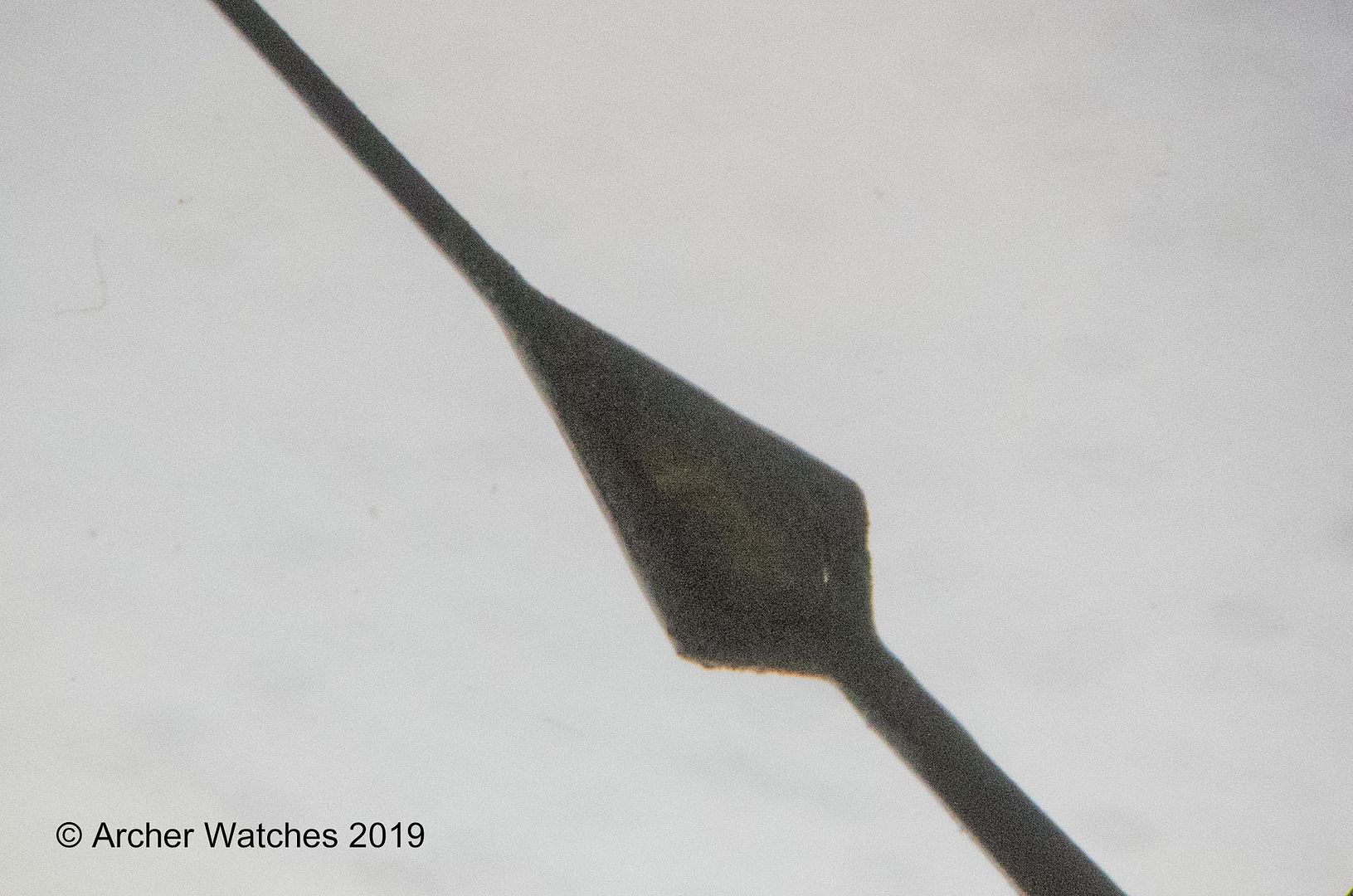

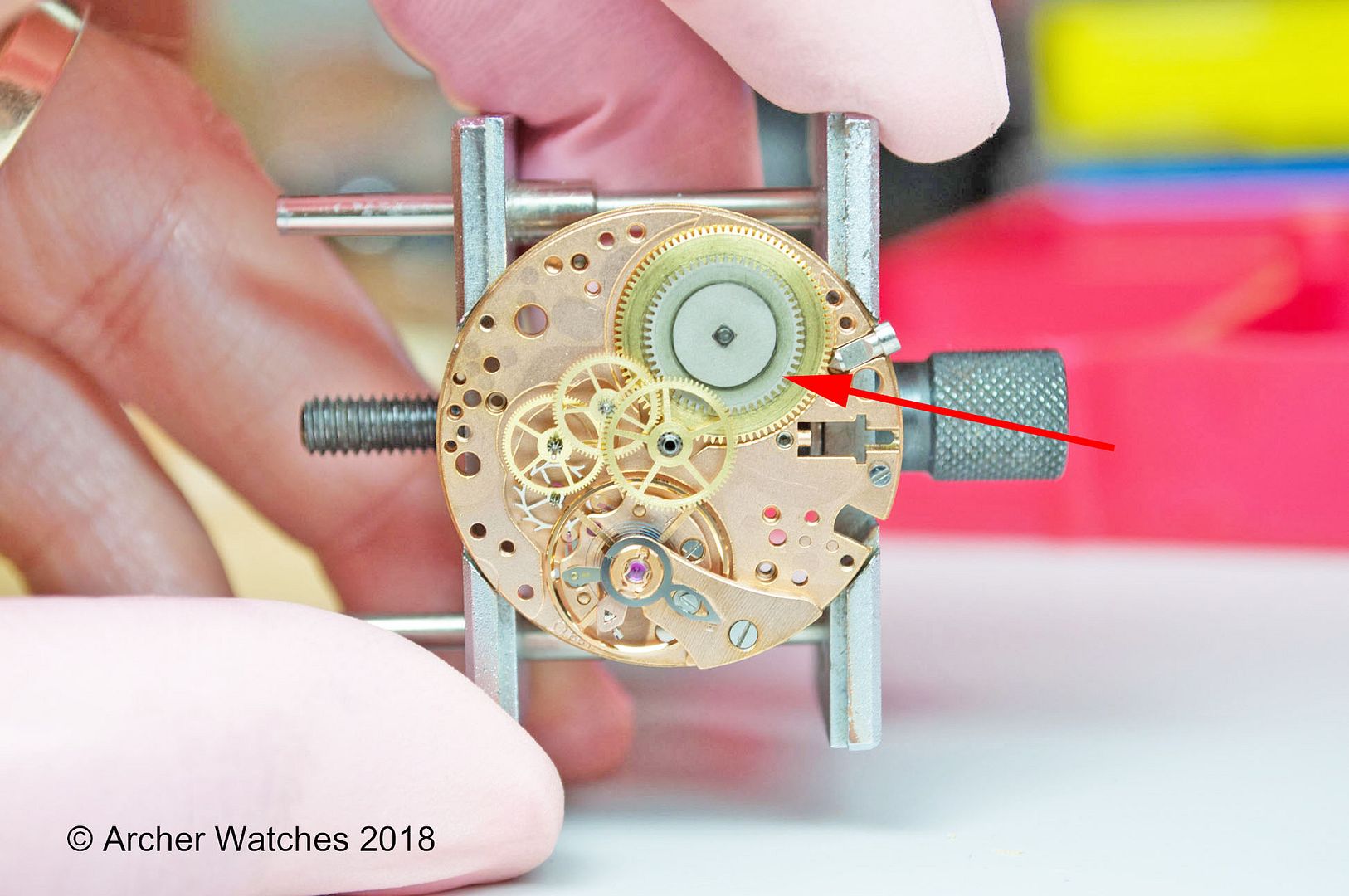

The barrel arbor doesn't go all the way through the plate, so the hole is stepped and you can see how much the hole has worn. This causes the barrel tip tilt inside the movement when it's under load, and you can often see wear marks on the ratchet wheel, like this dark ring:

This is where the ratchet wheel has been rubbing on the underside of that same bridge. Here you can see the shiny spot that rubbing has created:

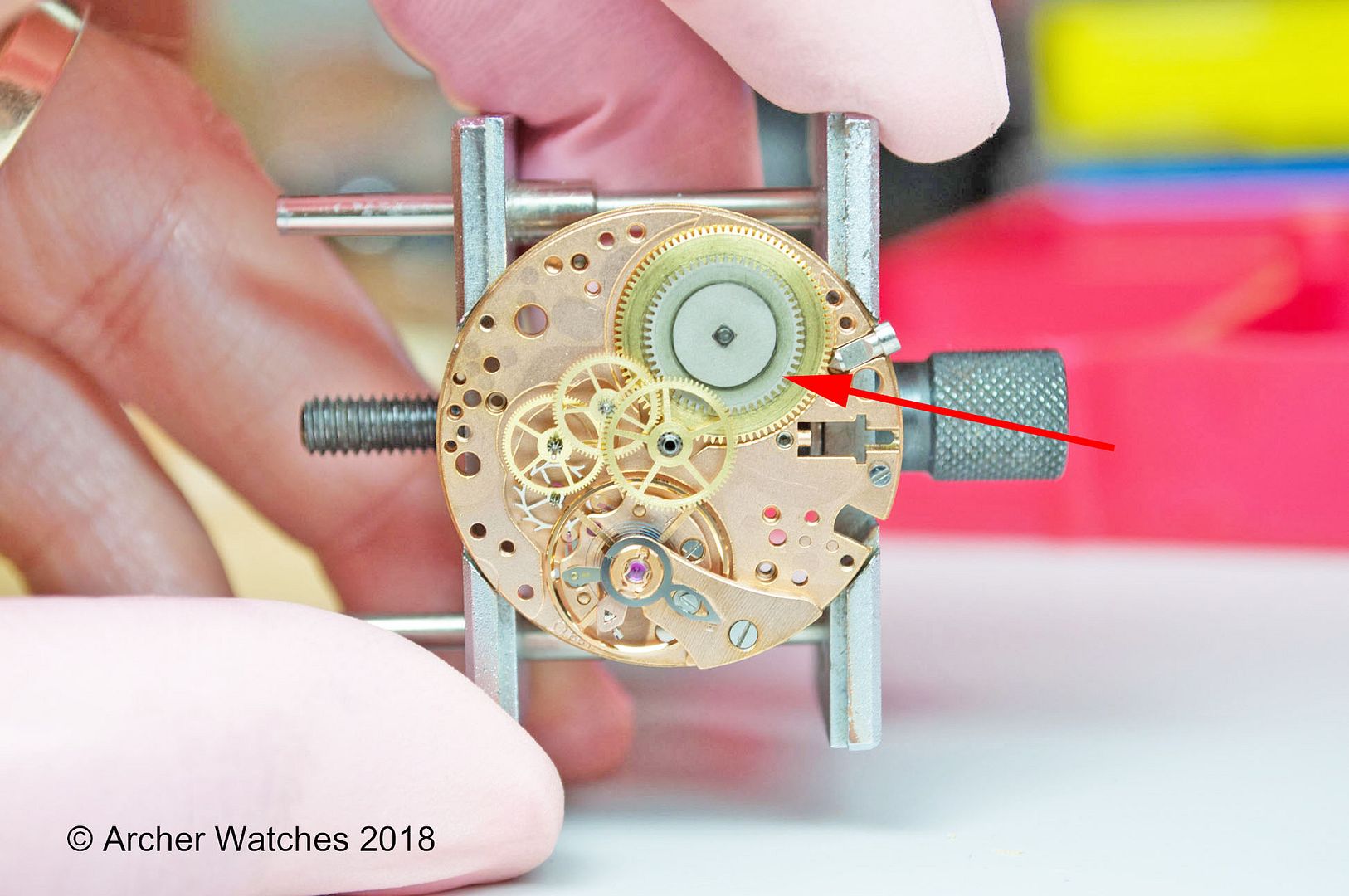

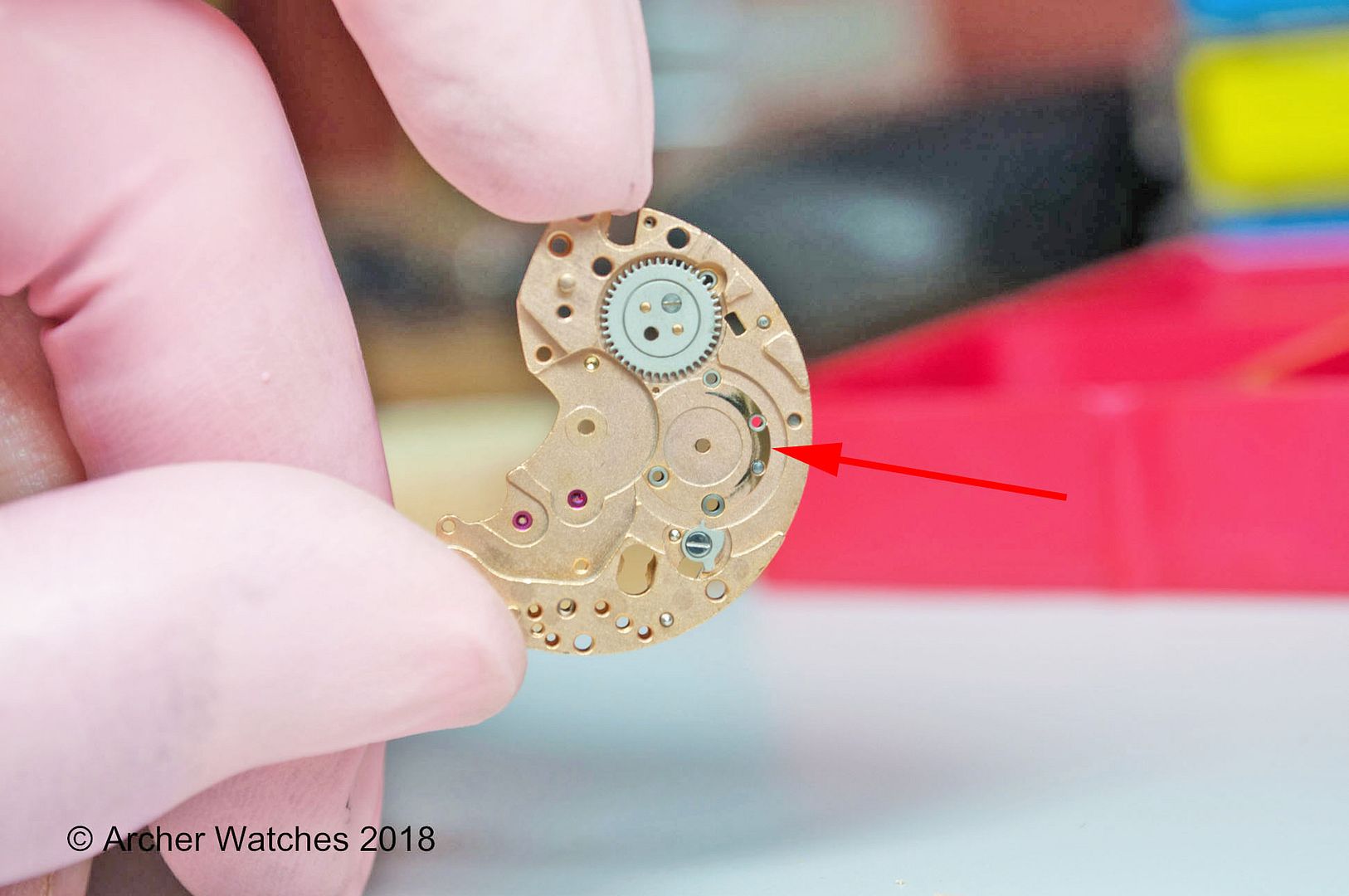

This causes a massive drop in balance amplitude, and to solve it, Omega replaces that entire bridge. Note that this bridge has numerous parts on it for all the chronograph functions, so posts and tapped posts that the chronograph parts all mount to - here is a photo where I have added red arrows to show all the items mounted on the top side of that bridge (and there are parts on the underside as well):

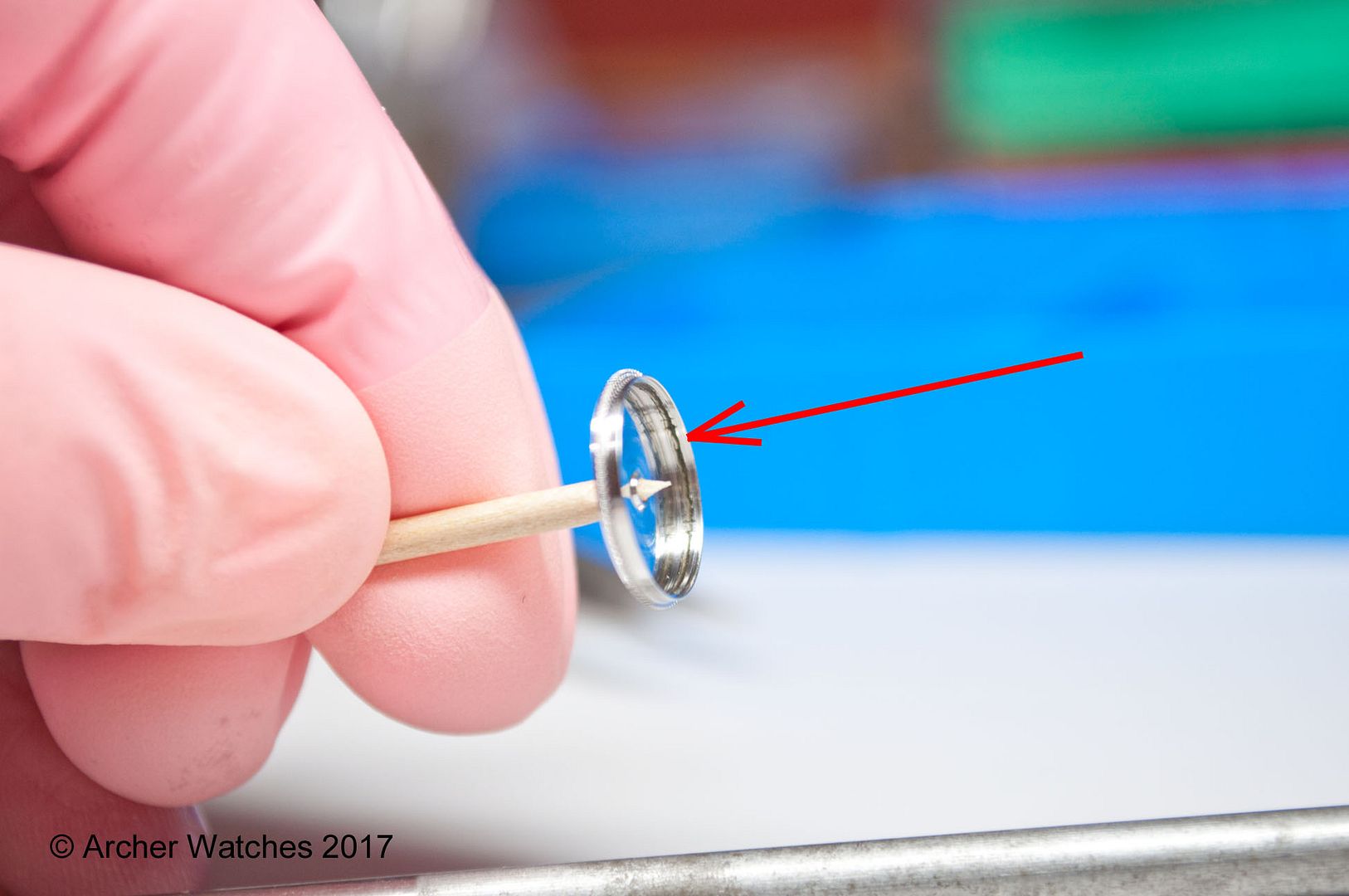

The bridge is a part that costs around $400 US to replace, and Omega just replaces it. A proper watchmaker will perform repairs, and since this is such a common problem I have a repair procedure to bore out the worn hole, and install a bushing to fit. This is the same bridge shown above, but with the new bushing fitted:

This is a simple repair that doesn't take long to perform, but the watchmakers at a service center would never do this. They just replace parts.

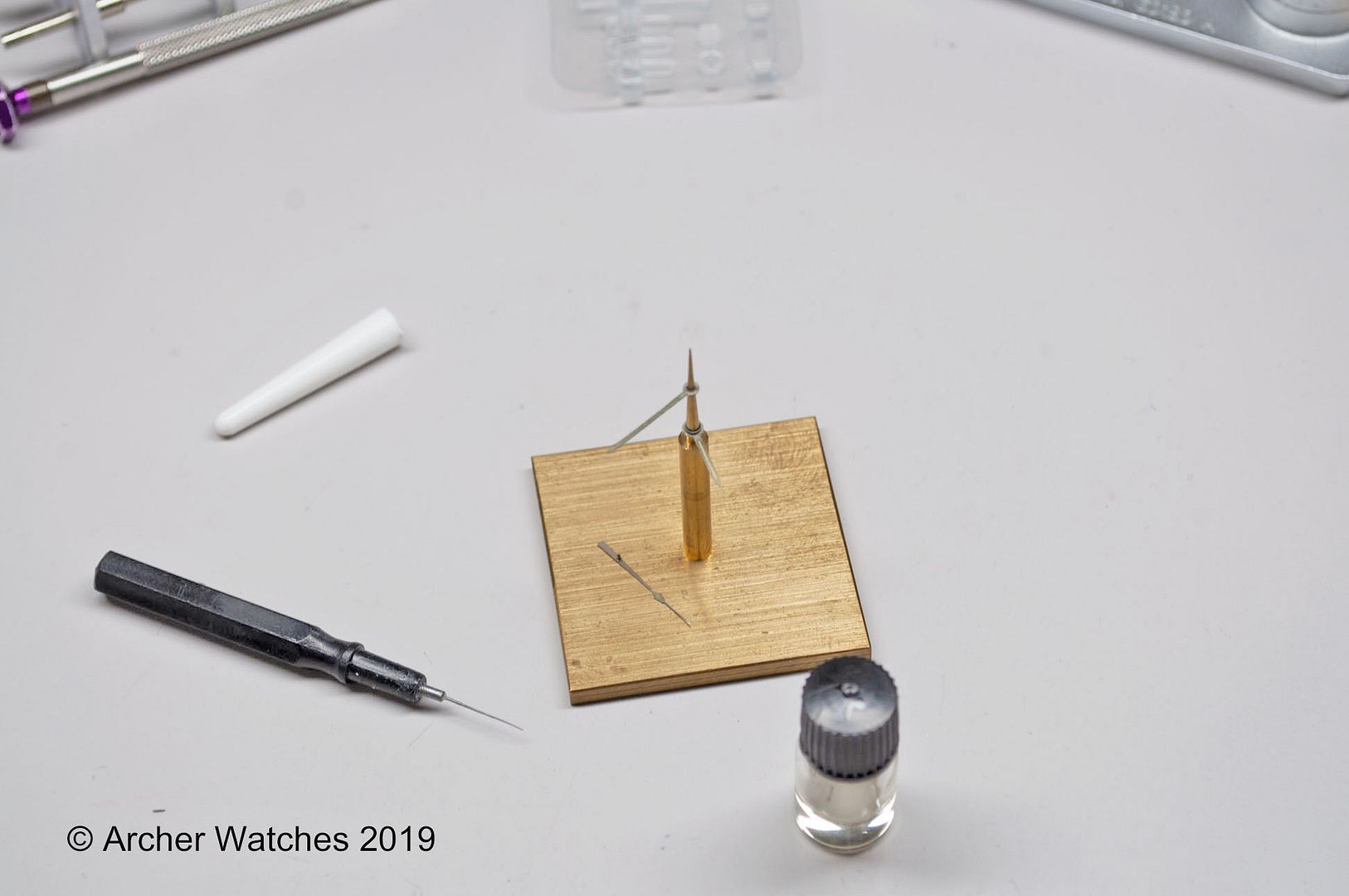

Similar situation with parts like hands. This is particularly important for vintage watches, as tritium hands are expensive to find as they are not made any longer. In a service center, hands are often replaced pretty much automatically. Often there is no real reason for this, as hands can be used over and over again. You can ask them to keep the hands, but if the service center finds that the lume in the hands may be cracked, like this:

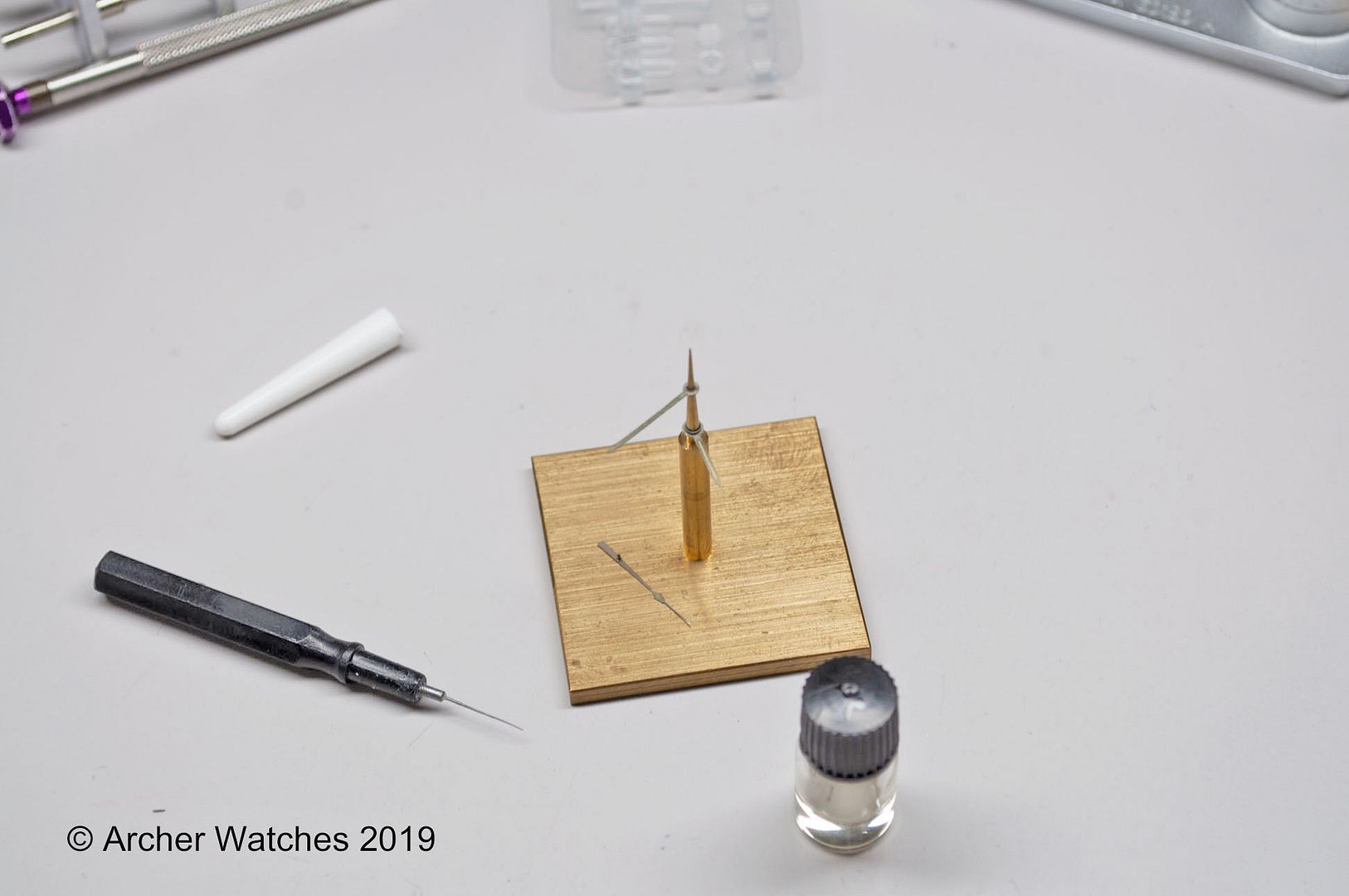

They will insist on replacing them. While that may seem to be a prudent thing to do (no one wants tritium flakes floating in the movement), there are other ways of handling this. Usiong clear binder that is mixed with luminous powder to form lume paste, the lume in hands like these can be stabilized:

The clear binder is applied to the back of the hands, and this ensures that the cracked lume won't fall out, and doesn't change the appearance of the hands:

This simply doesn't happen in a service center setting. They just take your nice tritium hands, toss them in a plastic bag with all kinds of other parts, and slap bright new stark white hands on your vintage watch. If you are lucky they come back to you without any addition damage.

I don't blame the watchmakers for this - it's the corporate policies and time constraints that cause this sort of thing to happen.

It is done to ensure that the watch won't come back under warranty, which is certainly a good goal, but the manner in which they get there is incredibly wasteful...

Cheers, Al